In the ever-evolving landscape of power tools, the choice between air-powered and electric models can significantly impact both performance and efficiency. Among these tools, reciprocating saws stand out for their versatility and power. This article delves into the advantages of using air reciprocating saws compared to their electric counterparts, highlighting their superior performance, portability, and operational efficiency.

Understanding the Basics: What is a Reciprocating Saw?

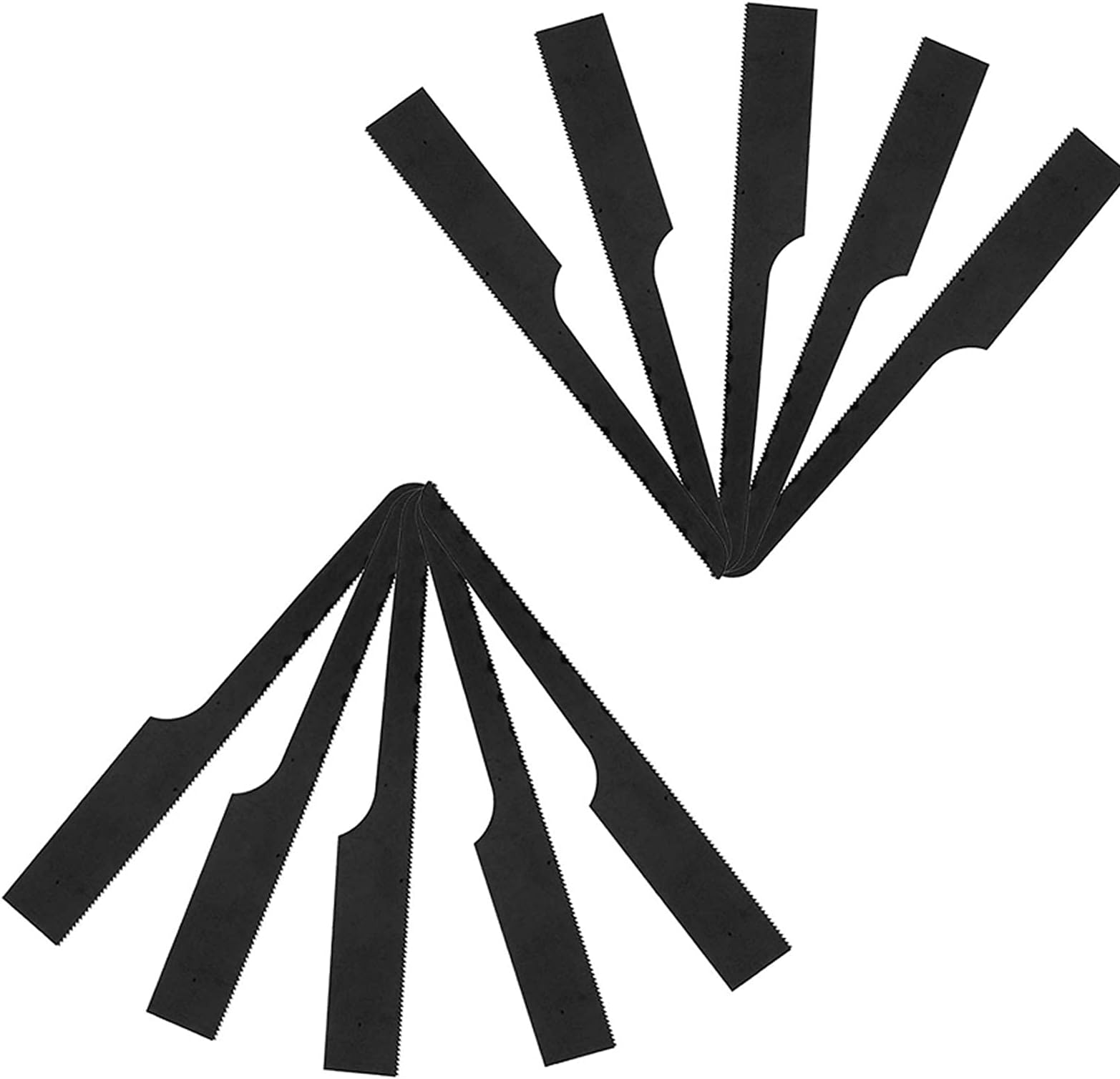

A reciprocating saw is a type of saw that moves a blade back and forth (reciprocates) to cut through various materials. They are commonly used in demolition, remodeling, and construction projects. Reciprocating saws come in two primary types: electric and air-powered (pneumatic). While both serve similar purposes, their operational mechanisms and advantages differ significantly.

1. Power and Performance

One of the most notable advantages of air reciprocating saws is their power output. Pneumatic tools are typically more powerful than electric models due to the mechanics of air pressure.

- Higher Power-to-Weight Ratio: Air-powered reciprocating saws generally have a higher power-to-weight ratio, allowing for more cuts per minute with less fatigue for the user.

- Consistent Performance: The performance of air saws remains consistent even under heavy loads, making them ideal for tough materials like metal and dense wood.

- Adaptable to Various Blade Types: Air saws can accommodate a wider range of blades, enhancing their functionality across different materials.

For instance, a study by the Power Tool Institute found that pneumatic saws could maintain peak performance even when cutting through tougher materials, outperforming electric models by up to 30% in specific tasks.

2. Efficiency and Speed

When it comes to efficiency, air reciprocating saws offer several advantages:

- Faster Cutting Speeds: The air-driven mechanism allows for faster cutting speeds, enabling professionals to complete tasks in less time.

- Continuous Operation: Unlike electric saws that may overheat with extended use, air saws can operate continuously as long as a steady air supply is available.

- Reduced Downtime: The ability to quickly switch between blades and maintain cutting speeds reduces downtime significantly.

A case study from a construction firm utilizing air-powered tools for demolition tasks revealed that they completed projects 25% faster than when using electric saws, attributing the difference to the efficiency of pneumatic tools.

3. Portability and Convenience

Portability is a crucial factor for professionals who often work in various locations. Air reciprocating saws have distinct advantages in this area:

- Lighter Weight: Air saws tend to be lighter than electric models, making them easier to handle and transport.

- No Batteries Required: Being air-powered eliminates the need for batteries, reducing the risk of running out of power mid-job and the associated delays.

- Flexible Hose Length: The use of an air hose allows for flexibility in movement and reach, which can be advantageous in tight spaces.

For example, a contractor working on a remote site without access to electricity found air reciprocating saws to be invaluable, as they could operate without needing generators or long extension cords.

4. Cost-Effectiveness and Maintenance

While the initial investment in pneumatic tools may be higher, their long-term cost-effectiveness is undeniable. Here are the reasons why:

- Lower Energy Costs: Air-powered tools generally consume less energy compared to electric tools, resulting in lower utility bills over time.

- Durability: Pneumatic tools are often more durable and can withstand harsher working conditions, leading to fewer repairs and replacement needs.

- Minimal Maintenance: With fewer electrical components, air reciprocating saws require less maintenance, translating to reduced costs for repairs and upkeep.

A report from the National Association of Home Builders highlighted that contractors who switched to air tools saw an average 15% reduction in maintenance costs over five years.

5. Safety Considerations

Safety is paramount in any construction or demolition environment. Air reciprocating saws offer unique safety advantages:

- Less Risk of Electric Shock: Since air tools do not rely on electricity, the risk of electric shock is significantly reduced, especially in wet or humid conditions.

- Reduced Overheating: Air saws do not overheat, which minimizes the risk of burns or tool failure during extended use.

- Better Control: Many air reciprocating saws come with features that enhance user control, such as variable speed triggers, making them safer to operate.

A construction site in Florida reported fewer accidents and injuries after transitioning to air-powered tools, attributing the improvement to the inherent safety features of pneumatic equipment.

6. Environmental Considerations

In an age where environmental impact is a growing concern, air reciprocating saws have notable advantages:

- Reduced Carbon Footprint: Air tools produce less greenhouse gas emissions compared to electric models, especially when powered by clean air systems.

- Less Noise Pollution: Pneumatic tools tend to operate more quietly than electric tools, contributing to a healthier work environment.

- Recyclable Materials: Many components of air tools are made from recyclable materials, further minimizing environmental impact.

Conclusion: The Case for Air Reciprocating Saws

In summary, the advantages of using air reciprocating saws over electric models are substantial. From superior power and efficiency to enhanced portability, cost-effectiveness, safety, and environmental benefits, air-powered tools present a compelling choice for professionals in construction, demolition, and remodeling. As the demand for efficient and versatile tools continues to grow, air reciprocating saws stand out as a practical investment for those looking to optimize their operations.

Ultimately, the choice between air and electric may depend on the specific needs of a project, but understanding the benefits of each can lead to more informed decisions that enhance productivity and safety on the job site.